The multi-cylinder hydraulic cone crusher has the advantages of high-efficiency crushing capacity, flexible and adjustable discharge port, intelligent protection system, stable and reliable performance, energy saving and environmental protection, and easy maintenance and maintenance.

In the field of mining crushing, cone crusher has always been the core equipment for medium and fine crushing operations. In recent years, multi-cylinder hydraulic cone crusher has gradually replaced traditional spring cone crusher and single-cylinder hydraulic cone crusher with its advantages of high production capacity, low energy consumption, and intelligent adjustment, becoming the first choice in the high-end crushing market.

• Multi-cylinder hydraulic cone crusher adopts coordinated control of multiple hydraulic cylinders (usually 4-8). Compared with single-cylinder models, it can more accurately adjust the size of the discharge port, ensure that the crushing chamber is always in the best state, and increase the output by more than 30%.

• Applicable scenarios: high-hardness ores (such as granite, basalt), large-scale sand and gravel aggregate production lines

• One-button adjustment of the discharge port: no need to stop the machine, real-time adjustment through the hydraulic system, reducing manual intervention.

• Over-iron protection: When encountering unbreakable objects (such as iron blocks), the hydraulic cylinder automatically releases pressure to protect the equipment.

• Automatic compensation for wear: After the liner is worn, the hydraulic system automatically adjusts the position to maintain a stable discharge particle size.

• The multi-cylinder hydraulic cone crusher adopts the principle of laminated crushing, which allows the material to be squeezed and ground multiple times in the crushing chamber. Compared with traditional impact crushers, the energy consumption is reduced by 15%-20%, which is especially suitable for areas with high electricity costs.

• Because the multi-cylinder hydraulic system can accurately control the motion trajectory of the moving cone, the finished aggregate after crushing has a more uniform particle shape and the needle-like content is less than 10%, which meets the needs of high-grade concrete such as high-speed railways and highways.

cone crusher price

Hydraulic cone crusher

Mining crushing equipment

Multi-cylinder hydraulic cone crusher

1. Multi-cylinder hydraulic cone crusher is suitable for large mines and high-hardness materials (such as granite and basalt). With the coordinated control of multiple hydraulic cylinders, it can achieve higher production capacity (90-1200t/h), more precise particle size adjustment and intelligent iron protection, but the maintenance cost is high;

2. Single-cylinder hydraulic cone crusher is more suitable for small and medium-sized sand and gravel plants and medium and low hardness materials (such as limestone). It has a simple structure and high cost performance, but the adjustment accuracy and production capacity (40-1000t/h) are relatively low. If you pursue efficient and intelligent production, choose multi-cylinder; if the budget is limited or you are processing medium materials, single cylinder is more economical.

• Large mines, high-hardness materials → choose multi-cylinder hydraulic cone crusher (such as HP500, HP800).

• Small and medium-sized sand and gravel plants, medium-hardness materials → single-cylinder hydraulic cone crusher is more cost-effective.

Multi-cylinder hydraulic cone crusher is widely used in medium and fine crushing of medium and high hardness ores (such as granite, iron ore), and is particularly suitable for large-scale sand and gravel aggregate production lines and modern intelligent mines that have strict requirements on the finished product particle shape.

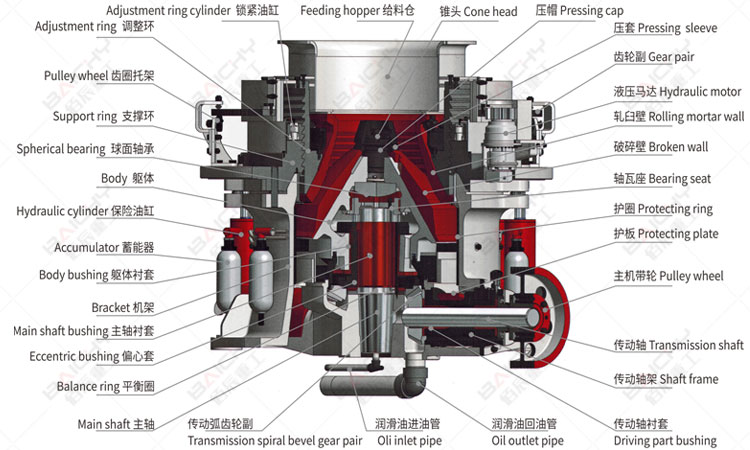

The working principle of the multi-cylinder hydraulic cone crusher can be summarized as the dual technical combination of "laminated crushing + hydraulic intelligent control". The core is to achieve an efficient and stable crushing process through the synergistic action of multiple hydraulic cylinders.

1. Dynamic extrusion: The main shaft drives the moving cone to perform eccentric swinging motion, so that the material in the crushing chamber is repeatedly squeezed and ground between the moving cone and the fixed cone liner.

2. Multi-stage crushing: The material falls in a "waterfall-like" manner in the crushing chamber and undergoes multiple laminated crushing (similar to a "sandwich" structure). Compared with single impact crushing, it can significantly reduce the proportion of needle-like particles.

3. Particle shape control: By adjusting the swing trajectory of the moving cone, the finished product particle size is made more uniform (needle-like content <10%).

| Model | Cavity Type |

Feed Openning Size(mm) |

Max Feeding Size (mm) |

Min Discharge Opening (mm) |

Capacity (t/h) |

Power (kw) |

|

HP100 |

Extra Coarse - EC | 140 | 110 | 19 | 65-140 | 90 |

| Coarse - C | 100 | 75 | 13 | 50-110 | ||

| Medium - M | 70 | 50 | 9 | 45-100 | ||

| Fine - F | 50 | 35 | 9 | 40-95 | ||

| Extra Fine - EF | 20 | 10 | 6 | 35-90 | ||

|

HP200 |

Extra Coarse - EC | 185 | 145 | 19 | 145-250 | 160 |

| Coarse - C | 125 | 100 | 16 | 135-235 | ||

| Medium - M | 95 | 75 | 13 | 115-220 | ||

| Fine - F | 75 | 60 | 10 | 90-190 | ||

| Extra Fine - EF | 54 | 45 | 12 | 81-190 | ||

|

HP300 |

Extra Coarse - EC | 234 | 190 | 25 | 220-445 | 220 |

| Coarse - C | 211 | 170 | 20 | 190-380 | ||

| Medium - M | 150 | 120 | 16 | 175-320 | ||

| Fine - F | 107 | 85 | 14 | 145-280 | ||

| Extra Fine - EF | 53 | 40 | 12 | 110-240 | ||

|

HP400 |

Extra Coarse - EC | 295 | 240 | 30 | 300-630 | 315 |

| Coarse - C | 251 | 200 | 25 | 285-560 | ||

| Medium Coarse - MC | 196 | 160 | 20 | 250-490 | ||

| Fine - F | 110 | 90 | 13 | 180-345 | ||

| Extra Fine - EF | 90 | 75 | 10 | 135-320 | ||

|

HP500 |

Extra Coarse - EC | 330 | 270 | 38 | 425-795 | 400 |

| Coarse - C | 290 | 230 | 30 | 370-700 | ||

| Medium Coarse - MC | 210 | 165 | 22 | 330-605 | ||

| Fine - F | 135 | 105 | 16 | 270-535 | ||

| Extra Fine - EF | 95 | 75 | 13 | 220-430 | ||

|

HP800 |

Extra Coarse - EC | 350 | 280 | 38 | 570-1200 | 630 |

| Coarse - C | 299 | 240 | 32 | 520-1050 | ||

| Medium Coarse - MC | 265 | 214 | 25 | 475-950 | ||

| Fine - F | 220 | 175 | 16 | 370-800 | ||

| Extra Fine - EF | 150 | 125 | 13 | 310-600 |

Have Any Questions!

Don't Hesitate To Contact Us AnyTime.

If you need further information,please fill in your questions and comments in the form below.

Representatives from Baichy machinery will be back to you within the hour,thanking you for your support to Baichy machinery